There are many ways to transport concrete to your pour site, and choosing the correct one for your needs will mean the final quality of your mix is not compromised. Concrete transportation happens in two stages: from batching plant to the worksite, and within the worksite itself. Your chosen method of transportation will largely depend on the application of your concrete and the setup of your construction site.

In this article, we’re looking at the various transportation methods for concrete, along with their benefits.

TRANSPORTING CONCRETE TO A WORKSITE

Once you’ve ordered a batch of concrete, it’ll need to be transported from the batching plant to your worksite. There are a two main methods of doing this:

- Concrete drum mixer (or ‘transit mixer’) – the most common and recognisable option, the concrete mixer is a truck-mounted revolving drum which can either mix your concrete during transportation, or keep premixed concrete agitated until it reaches your site.

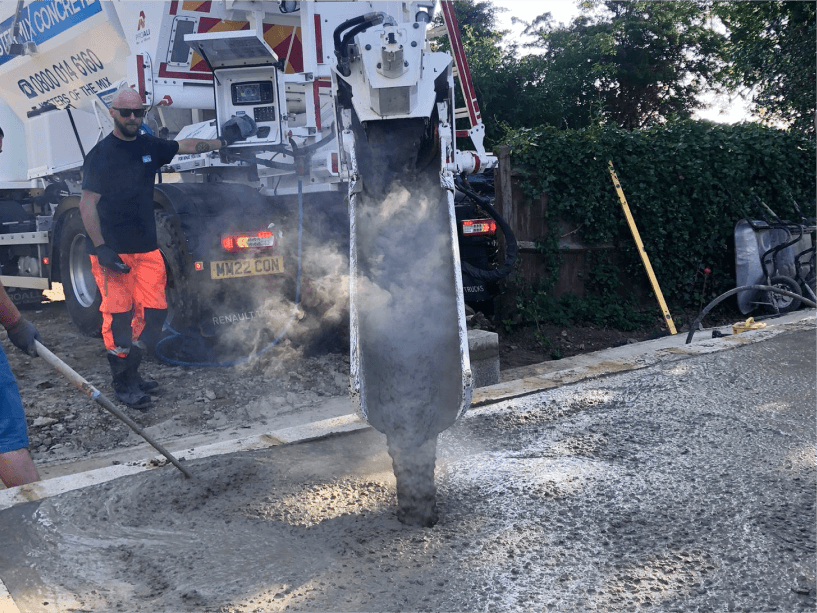

- Volumetric mixer – Basically a mobile batching plant, a volumetric mixer transports the base ingredients of concrete to your site, mixing it for you either before it reaches you or once it is at your site. The main benefit of volumetric mixers is how you can change the required mix as necessary once it arrives art your worksite. This is helpful for worksites where demands might fluctuate.

TRANSPORTING CONCRETE WITHIN A WORKSITE

Once the concrete has been delivered, there might be a need to transport the mix deeper into the worksite itself. There are many options at this stage, and your chosen method will depend heavily on the location of the pour site and the condition of the worksite in general. Some of these methods involve manual labour, while others utilise a more sophisticated network of pipes, chutes or pumps.

Here are some of the most efficient and popular methods of transporting concrete within a worksite:

- Wheelbarrow and shovel – a basic way to transport small mixes across short distances. In order to properly use this method, your worksite should be flat, easy to navigate, safe and with a clear, unopposed route directly to your pour site. You’ll also need the necessary workers to ensure the full mix is transported in time.

- Chute – usually used for when concrete needs to be poured at depth below ground. Chutes should only be used in short stretches, and the mix needs to be easily workable – so it can easily be transported down the chute without risking separation.

- Pumps – There are three forms of concrete pumps: boom pumps, line pumps, and specialised usage pumps. Unless your worksite is a mine or network of tunnels, the specialised usage pump won’t be relevant. Boom pumps use an articulated, remote controlled robotic arm (or ‘boom’) to quickly deliver large volumes of concrete to high locations or to sites where access is blocked by walls, fences or other tall obstacles. Line pumps use a series of pipes to pump concrete across sites which are tough to navigate – due to obstacles, challenging topography – or through buildings. Line pumps are slower than boom pumps, but can cross long distances.

- Belt conveyor – used to continuously transport concrete through a worksite, belt conveyors are versatile and able to transport large amounts of concrete both horizontally and at an incline. Belt conveyors are useful when transporting a large volume of concrete quickly in sites where space is limited.

FACTORS THAT AFFECT TRANSPORTATION

There are a few factors which will influence your choice of transport for your concrete mix. Most of these are logistical aspects, while some will rely on the kind of mix you order in the first place. These factors include:

- The location of your worksite

- The distance from the batching plant

- Ease of access to your worksite

- Seasonal and weather complications

- Size of your worksite

- Number of workers available

- Location of pour site

- Topography of your worksite

Successfully transporting concrete requires forethought and strategic planning. Making an unsuitable choice at any stage will likely lead to a compromised final product, leading to weaker concrete structures that will require repair or, more severely, demolition and rebuilding.

There is a close relationship between efficient, appropriate transportation and the success of your construction project. That’s why it is essential to coordinate delivery and conveyance of concrete to meet the specific requirements and applications of your project.

- ANY SIZE

ORDER - FREE NO

OBLIGATION QUOTES - ONLY PAY FOR

WHAT YOU USE - SAME DAY/

NEXT DAY DELIVERY

AREAS WE COVER

We deliver concrete of any size order to Watford and the

surrounding areas. We promise fast, same or next day deliveries and

an efficient service every time.